AR VR SERVICES

One of the hardest things to do in technology is disrupt yourself

-Matt mullenweg.

Virtual Reality / Augmented Reality Safety In Manufacturing

HR has a large challenge today because they are retraining for the same position with significant turnover in many positions.

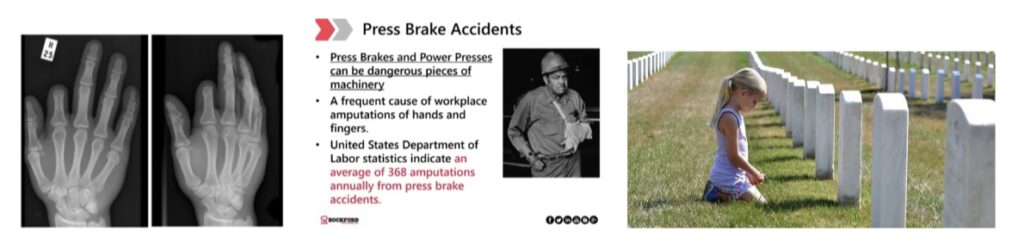

Safety – most injuries occur to employees on the job less than 120 days.

OSHA – attributes this safety problem to the lack of sufficient training.

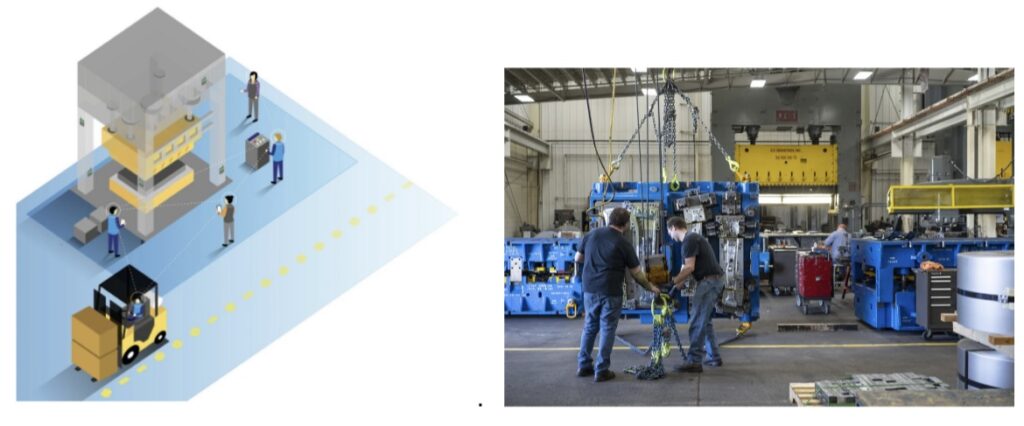

Difficulties in training

On the floor training distractions,

Noise, difficult to hear or concentrate.

Hazards, forktrucks and overhead cranes in close proximity.

.

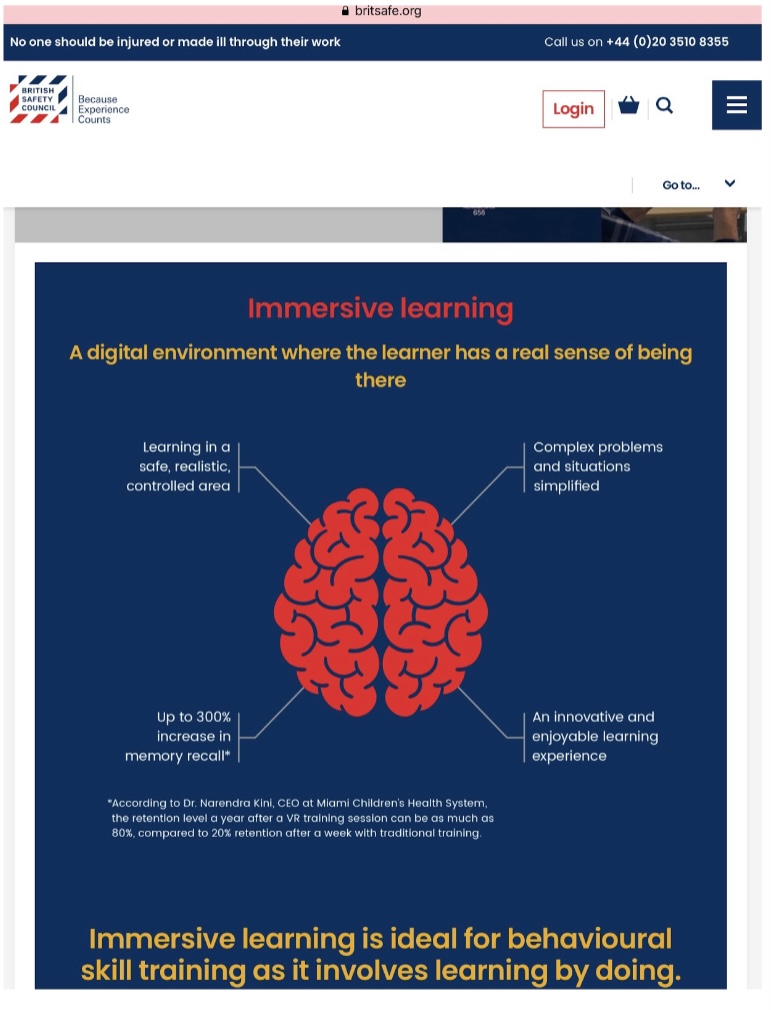

Solution: VR and AR training of the equipment and safety procedures.

More effective than video training where the student is not fully immersed and not engaged.

Retention is higher when developing muscle memory of the process by actually doing to process in VR (80% VR / AR vs 20% tradition training retention)

Virtual Reality

Training on the equipment in a quiet, remote location free from hazards and disruptions providing better retention of information.

Instead of Training here…. Train Anywhere!

Utilize Virtual Reality for greater safety and better retention.

Augmented Reality phase 2

Seeing hazardous areas through vision system

Without AR With AR

.

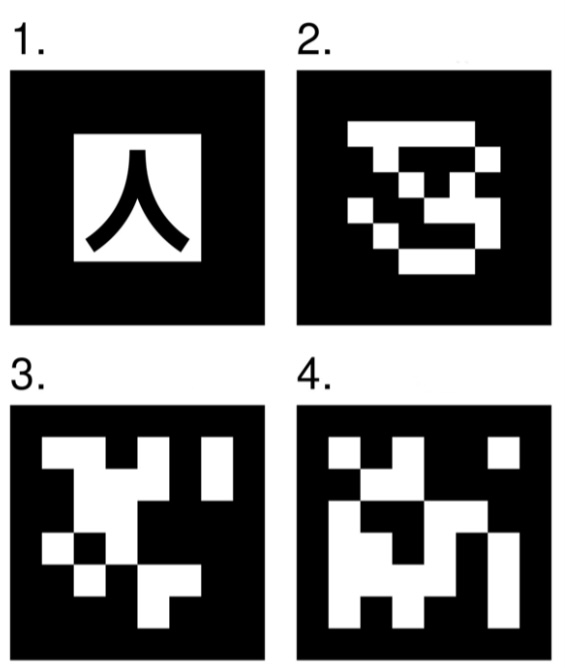

Hazardous area are identified by mapping and visual identification using fiducial tags and RFID identifiers

Augmented Reality phase 3

Calculating Safety Areas

| velocity | reaction t | scan time | stop time | distance | Fiducial |

| mach 1 | 20 spm | .032 sec | .187 sec | 11.8 “ | 1 | ||

| mach 2 | 50 spm | .032 sec | .258 sec | 16.25 “ | 2 |

Wrist sensors monitor your hands position and vibrate to tell you when you are near a hazardous area.

Benefits of VR / AR training:

Company

Lower premiums (removal from high risk pool), increased employee confidence, better training and improved employee retention for operations and safety.

Employees

Safer training, reduced risk, better job comprehension and improved feeling of welfare.

Community

Every employee’s child has the right to know their parent will come home safely from their job.